In today’s energy-dependent world, gas piping systems play a crucial role in safely and efficiently transporting natural gas or propane to homes, businesses, and industries across Scandinavia and the EU. Selecting the right gas pipes isn’t just about picking the cheapest option—it’s about prioritizing durability, cost-effectiveness, and above all, safety to comply with stringent EU regulations like those from the European Committee for Standardization (CEN). With options ranging from traditional metals to modern plastics, understanding the pros and cons can help you make informed decisions for your next project.

This comprehensive guide explores four popular types of gas pipes, key selection factors, and emerging trends in gas piping technology. Whether you’re a homeowner in Sweden upgrading your heating system or a contractor in Denmark handling industrial installations, this article will equip you with the knowledge to choose wisely.

Why Choosing the Right Gas Pipe Matters in Scandinavia and the EU

Gas pipes ensure reliable delivery of fuel for heating, cooking, and industrial processes. Globally, over 1 billion consumers use more than 8 trillion cubic meters of natural gas annually, with a significant portion relying on robust piping infrastructure in regions like Scandinavia, where harsh winters demand dependable systems.

The wrong choice can lead to inefficiencies, costly repairs, or dangerous leaks – issues that EU directives, such as the Gas Appliance Regulation (EU) 2016/426, aim to prevent. Factors like environmental conditions (e.g., cold Nordic climates), pressure requirements, and local building codes in countries like Norway or Finland heavily influence the best pipe type.

For more insights on energy solutions, check out our latest news on sustainable infrastructure.

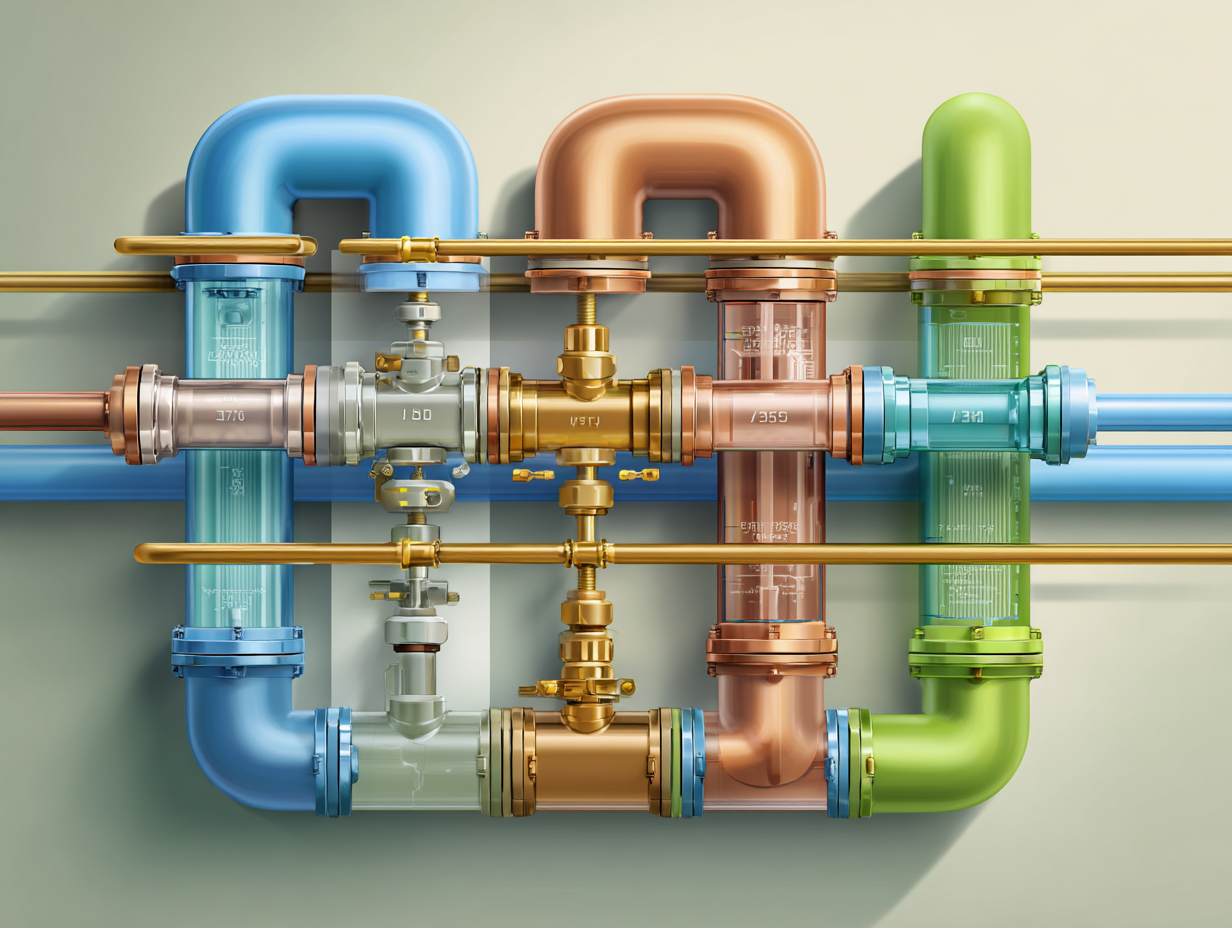

The 4 Main Types of Gas Pipes: A Detailed Comparison

1. Steel Pipes: Durable Choice for High-Pressure Needs

Steel pipes have long been a staple in gas piping, prized for their strength and longevity, making them ideal for demanding applications in Scandinavian industrial sectors.

Common Applications:

- High-pressure industrial and commercial systems, such as those in oil refineries or manufacturing plants in Sweden.

- Outdoor installations exposed to extreme weather, like freezing temperatures in Norway.

Advantages:

- Exceptional toughness against high pressure and physical damage.

- Long lifespan of 50-100 years with proper maintenance.

- Reliable for critical infrastructure under EU safety standards.

Drawbacks:

- Heavy and labor-intensive to install, often requiring specialized skills.

- Susceptible to corrosion without protective coatings, increasing maintenance in humid EU coastal areas.

Industry Insight: Steel remains the go-to for power plants and factories where reliability is non-negotiable, aligning with Scandinavian emphasis on sustainable, long-term energy solutions.

2. Copper Pipes: Flexible and Corrosion-Resistant for Residential Use

Copper is a favored material for indoor gas systems in EU homes, offering ease of installation and aesthetic appeal.

Common Applications:

- Indoor setups for appliances like stoves and heaters in Danish or Finnish residences.

- Low- to medium-pressure systems in small commercial spaces.

Advantages:

- Highly resistant to corrosion, reducing maintenance needs in moist Scandinavian environments.

- Flexible for navigating tight spaces during installation.

- Visually appealing, often left exposed in modern EU designs.

Drawbacks:

- Higher cost, ranging from €2.50 to €3.50 per linear meter.

- Can degrade from sulfur in natural gas without additives.

Interesting Fact: In regions with sulfur-rich gas supplies, EU-approved additives extend copper pipe life, ensuring compliance with safety norms.

3. Polyethylene (PE) Pipes: Ideal for Underground Installations

PE pipes are gaining popularity in the EU for their flexibility and resistance to corrosion, especially in underground networks.

Common Applications:

- Underground natural gas distribution in housing developments across Scandinavia.

- Long-distance lines in industrial estates.

Advantages:

- Lightweight, saving up to 30% on installation time and costs compared to metal pipes.

- Naturally resistant to rust, corrosion, and chemicals—perfect for EU’s variable soils.

- Suitable for low- to medium-pressure systems with a 50+ year lifespan.

Drawbacks:

- Not recommended for high-pressure or high-temperature applications.

- Requires specialized fittings for secure, leak-free joints.

Quick Fact: PE pipes’ durability makes them a cost-effective choice for sustainable urban planning in cities like Stockholm or Helsinki.

4. Polyvinyl Chloride (PVC) Pipes: Budget-Friendly for Low-Pressure Systems

PVC offers an affordable option for non-pressurized gas applications, though its use is limited by EU regulations.

Common Applications:

- Temporary or venting systems in small-scale EU projects.

- Basic gas distribution where technical demands are low.

Advantages:

- Low cost at €0.50–€1.00 per linear meter, ideal for budget-conscious installations.

- Easy to cut and install, minimizing labor time.

- Resistant to certain chemicals, extending life in specific setups.

Drawbacks:

- Unsuitable for high-pressure or extreme temperatures, especially in cold Scandinavian winters where brittleness increases.

- Check local codes, as some EU areas restrict PVC for gas due to safety concerns.

Pro Tip: Always verify compliance with national standards, like those in Germany or the Netherlands, before using PVC.

Key Factors to Consider When Selecting Gas Pipes in the EU

Choosing gas pipes involves balancing performance, cost, and safety under EU frameworks.

- Gas Flow Requirements: Pipe diameter affects capacity, residential needs might be 30,000-50,000 BTUs, while industrial could exceed 1 million.

- Pipe Length and Pressure Drop: Expect 1-3% drop per 100 meters; material choice impacts efficiency.

- Environmental Factors: Nordic cold and moisture favor corrosion-resistant options like PE or coated steel.

- Budget and Maintenance: Initial costs vs. long-term savings, durable materials like steel pay off over time.

Explore more on piping innovations in our news section.

Essential Gas Pipe Fittings and Their Role

Fittings ensure secure connections and prevent leaks:

- Couplings: Join pipe sections.

- Elbows: Redirect flow at 45° or 90°.

- Tees: Branch gas lines.

Use matching materials to avoid issues, as per EU installation guidelines.

Prioritizing Safety and Compliance in Scandinavian Gas Piping

Adhere to EU regulations on pressure ratings, materials, and installation to minimize risks. Avoid common pitfalls like using unrated materials or skipping permits. Proper compliance can cut accidents by over 50%, according to U.S. benchmarks adaptable to EU contexts.

The Future of Gas Piping: Trends Shaping Scandinavia and the EU

- Smart Piping: Sensors for real-time leak detection, enhancing safety in smart cities.

- Eco-Friendly Materials: Biodegradable options to reduce environmental impact, aligning with EU Green Deal goals.

- Efficiency Improvements: Advanced designs for lower energy loss.

The global gas pipeline market is projected to grow at 4.3% CAGR, driven by natural gas demand and tech advancements.

Conclusion: Making the Smart Choice for Your Gas Piping Needs

From robust steel to flexible PE, each gas pipe type offers unique benefits tailored to Scandinavian and EU applications. Consider pressure, environment, and regulations to ensure safety and efficiency. As innovations emerge, gas systems will become even more sustainable.

For the latest updates on gas infrastructure, visit our news page. Contact us for expert advice on your project!

From robust steel to flexible PE, each gas pipe type offers unique benefits tailored to Scandinavian and EU applications. Consider pressure, environment, and regulations to ensure safety and efficiency. As innovations emerge, gas systems will become even more sustainable.

For the latest updates on gas infrastructure, visit our news page. Contact us for expert advice on your project!