ABOUT KONTI HIDROPLAST

PIONEERING PIPE SOLUTIONS FOR URBAN DEVELOPMENT

About Us

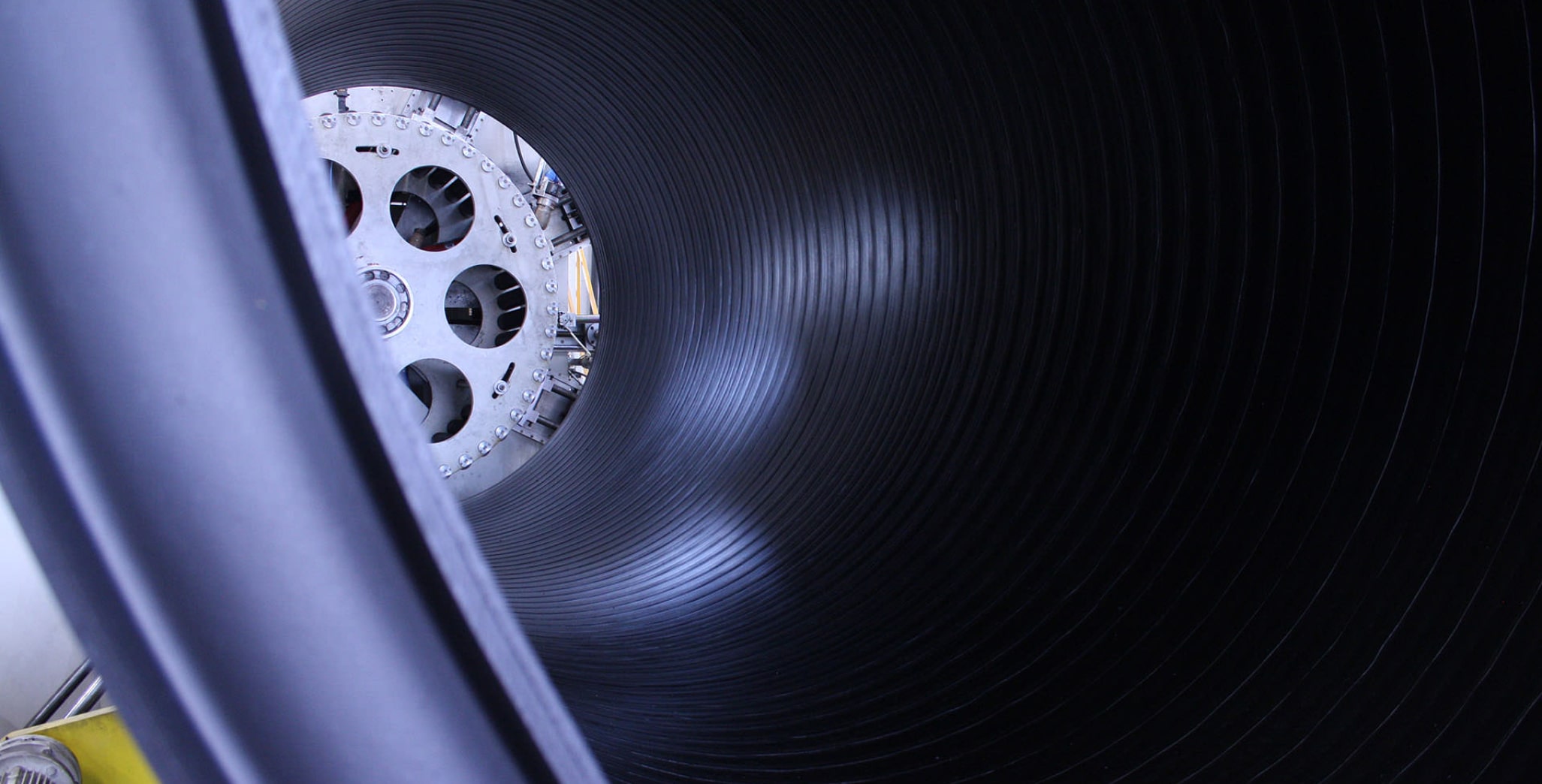

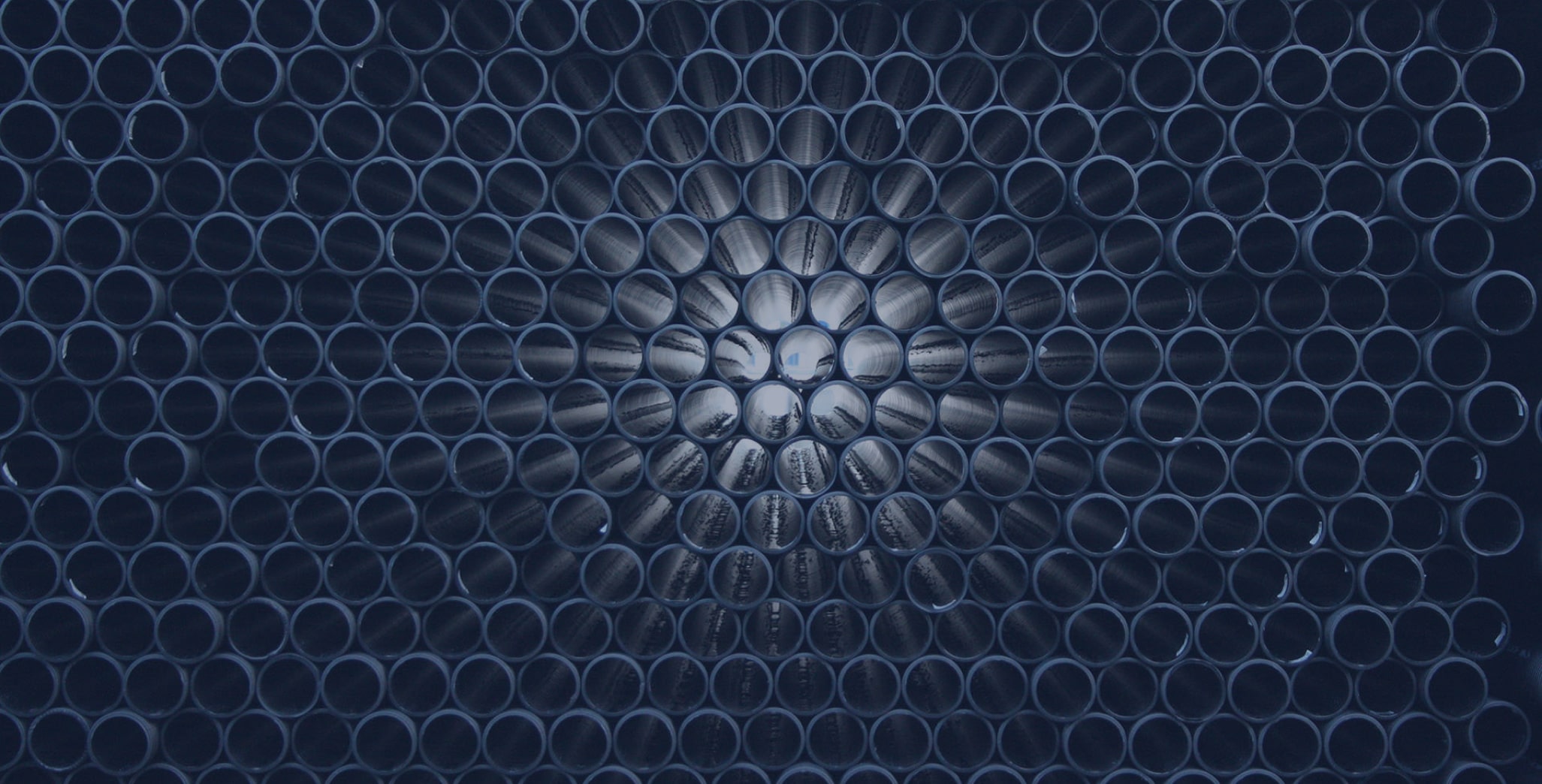

Konti Hidroplast is an export oriented Macedonian company for production of PE (polyethylene) and PP (polypropylene) pipes. Situated in the southern area of North Macedonia, municipality of Gevgelija, Konti Hidroplast was founded in 1975 as a small plant for production of tools and elements of injection molded plastic.

Following the successful start aided by the experience gained by successfully realized projects in the Republic of North Macedonia, today our company is export-oriented, and 95% of its products are exported in international markets.

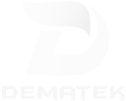

Besides the experience, our large range of products and top quality, by all internationally recognized standards, enabled us to get access to international markets. Our current production program covers all fields of application: pipes and hoses for water supply systems, sewage systems, PE and PP manholes, pipes for transporting gas and oil products, pipes and hoses for protection of telecommunication cables, drainage systems and fittings for all dimensions, which also range from a minimum diameter of 12mm up to 2000mm.

Konti Hidroplast became known to the market through quality supply and constant application of flexibility in operation, which is very important in an industry where the complexity of managing all processes is quite high.

One of the key factors for sustainability despite tough competition is constant reinvestment in innovative technologies and pursuing general technological progress. The combination of all these key factors are contributing for Konti Hidroplast to play an important role in the domestic and foreign markets with the constant presence of all major and minor infrastructure projects.

Mission

Promoting new technologies while adhering to stringent EU standards. With certified quality and competitive pricing, we embrace regulations and ecological responsibility.

Vision

A modern factory, a leader in the region for development and production of plastic products for infrastructure buildings, within the frames of an environmentally safe system with maximum safety for all stakeholders.

Values

At Konti Hidroplast, we’re dedicated to leading the industry with top-quality, eco-friendly pipes while prioritizing environmental protection and employee safety.

1990

1994

1996

1998

1999-2000

2002

2003

2004

2006

2008

2009

2011

2013

2014

2015

2016-2017

2018

2019

2020-2021

2022

Beginnings

Konti Hidroplast has started its manufacturing production in 1990 with one single production line of polyethylene pipes, with a total number of 10 employees.

New products and production lines

By 1994, the production program expanded with an additional 5 production lines. In addition to polyethylene hoses and LDPE pipes, Konti Hidroplast began to expand its production program with new types of products and the development of a wider range of dimensions.

With the development of new classes of polyethylene (PE), the use of PE pipes for household installations and pressure systems also expanded. With the use of second-generation polyethylene, such as PE63 and PE80, we started producing pipes for domestic installations with a pressure capacity of up to 16 bars. The range of dimensions increased with pipes up to F110mm.

Third Generation

In 1996 were manufactured the first pipes of a third generation polyethylene material, specifically PE 100.

This allowed the pipes to be used in installations with a working pressure of 32 bars.

That year, we also began producing gas transportation pipes for use in installations with a working pressure of 10 bars, as well as pipes that can be used in various other industries.

We increased the range of dimensions once again, with the largest dimension now being F160mm.

ISO 9001

In 1998 the dimensional range is increased once again. Now, the largest dimension being F250mm. That year, Konti Hidroplast obtained the ISO 9001 certificate for its management quality system.

International Offices

In 1999-2000 Konti Hidroplast began expanding its representations with opening its first offices abroad in Serbia and Bulgaria. But, the expanding did not stop there, today Konti Hidroplast has office representations in all of the Balkan countries.

In 2001 Konti Hidroplast achieved the greatest expantion of its production capacities to that date with the acquisition of two complete extrusion lines.

The first extrusion line expanded the range of pipes for domestic installations, producing pipes up to F400mm, while the second extrusion line was intended for the production of double-layer polyethylene pipes for sewage with dimensions up to F315mm.

That year, in addition to the ISO 9001 certification, we also received the ISO 14001 certification for the environmental management system.

New capacities

In 2002, the company expanded its capacities and product range with an additional production line for household installations, as well as sewage pipes with dimensions up to F630mm.

New International Offices

In 2003 were opened new company representations in Albania, Bosnia & Herzegovina and Croatia.

New Product

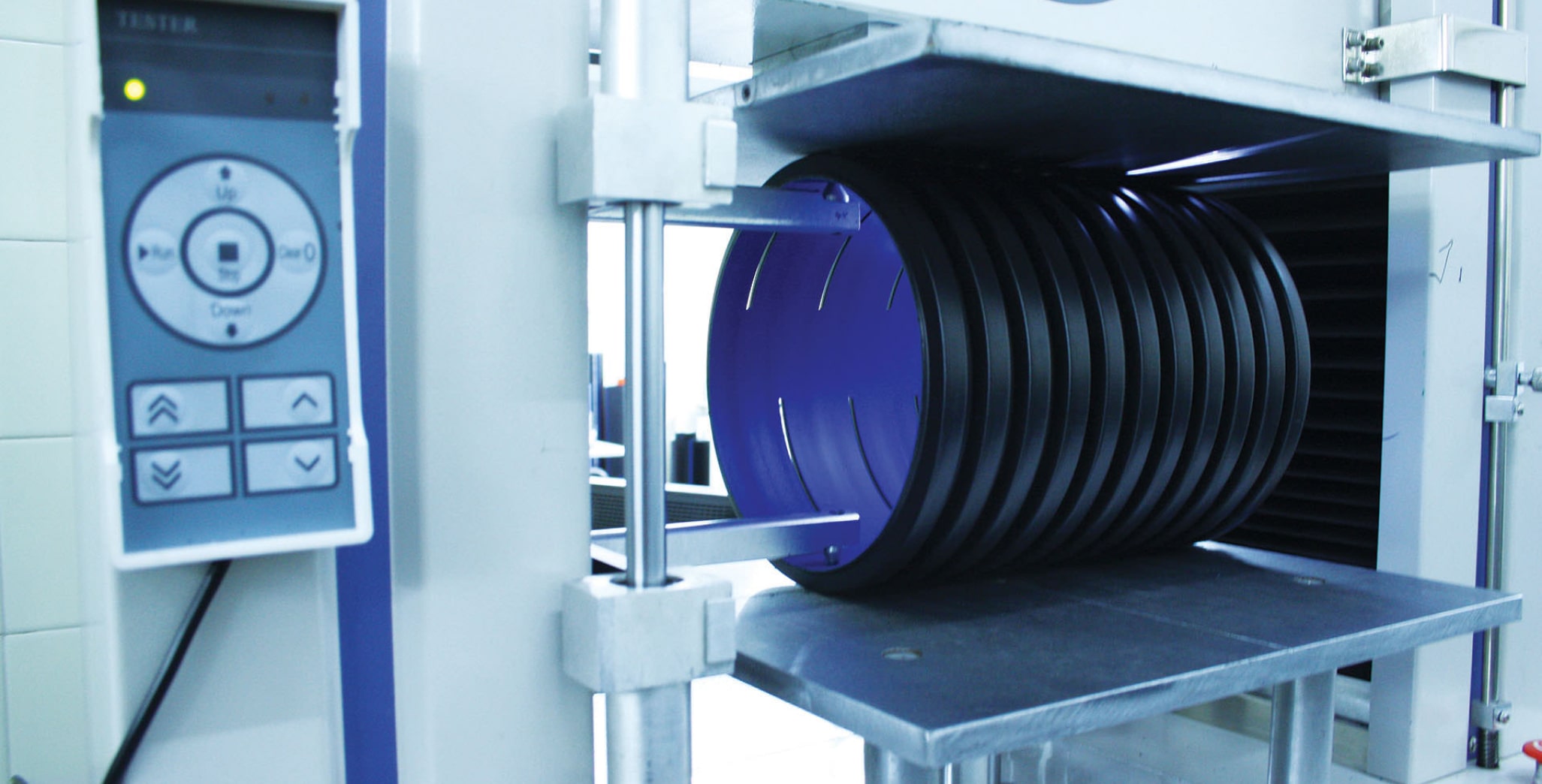

In 2004 began the production of a new product, the spiral sewage pipes with a diameter up to F1200mm.

New Production Line

In 2006 was installed a new production line for ribbed double-layer pipes with a diameter of up to F1200mm

New Capacity Increase

In 2008, we increased the production capacity of ribbed pipes with an additional production line, as well as a line for pressure pipes.

PP HM

In 2009, Konti Hidroplast expanded its production lines and product range with a new product, the PP HM pipes.

New Line and Machines

Two new injection molding machines for the production of sewer fittings and a new production line for spiral pipes in the dimensional range of 1300-2000 mm.

Expansion and Renovation

Expansion of the factory’s storage space with new areas

A new production line for pressure pipes up to 110 mm in diameter

Two new machines for perforating pressure pipes

Complete renovation of the area surrounding the factory

New Production Line

A new production line for pressure pipes up to F 500 mm and reorganization of production capacities and separation of fitting production from extrusion

OD 1000

Replacement of the OD 1000 line with a new European-made line for pipes up to F 630 mm

Expansion of the ID 1000 production line to include the OD 1000 dimension

New Acquisitions

- Procurement of a “cross head” extrusion die for the production of PE 100 RC Type 3 with an external protective layer (PE or PP) in dimensions ranging from 75 to 400 mm

- Procurement of an injection molding machine with a capacity of up to 20 kg per shot

- Acquisition of two new scanners, eccentricity indicators from the beginning of the process

OD 315

Replacement of the base of the oldest corrugator (OD 315) with a new one.

Two New Halls

Construction of two new halls for storing raw materials

New Hall with Three Production Lines

Construction of a new hall to expand production capacities

Installation of three new production lines for pressure pipes:

20-63 mm with a capacity of 300 kg/h

63-250 mm with a capacity of 600 kg/h

250-630 mm with a capacity of 1000 kg/h

New Corrugated Pipe Line and New Machines

A new high-productivity, energy-efficient production line for corrugated pipes in the 160-315 mm dimensional range

Improvement of the corrugated pipe production process by enhancing the welding of fittings, including the acquisition of three automatic inline welding machines for fitting attachment to pipes

At Konti Hidroplast, our mission has always been clear: to lead with innovation, deliver quality by European standards, and stay ahead of the curve in our industry. We are committed to creating sustainable solutions, expanding into new markets, and sharing knowledge with all who seek to grow. Together, we build not just for today, but for a future our next generations will be proud of.

Boris Madjunkov

General Director

Lazar Vacev

Angel Stojanov

Dijana Chochkova

Zafir Brzilov

Dusko Dojranliev

Vasko Sepetovski

David Rizov

Dimitar Madzunkov

Zorica Lozanovska

Gordana Manoleva

Kostadin Linkov

Bojan Georgiev

Risto Varela

Ana Varela

Pepica Kostova

Sanja Vaceva

Mimi Stojanova