Gas piping systems are essential for delivering natural gas or propane to homes, businesses, and industries. Whether building a new property or upgrading an existing system, understanding gas piping ensures safety, efficiency, and reliability. This guide covers materials, sizing, safety standards, maintenance, and future trends. With the global natural gas market projected to grow from $3.56 trillion in 2022 to $5.14 trillion by 2030, per Statista, choosing the right piping solution is critical.

At Konti Hidroplast, we offer durable piping solutions to meet these demands. Learn how to optimize your system for performance and sustainability.

What Is Gas Piping?

Gas piping systems transport natural gas or propane for heating, cooking, or industrial processes. These systems must meet strict safety standards to operate efficiently. The International Energy Agency projects a 1.5% annual increase in global natural gas demand through 2040, emphasizing the need for sustainable solutions.

Stay updated on industry trends in our news section.

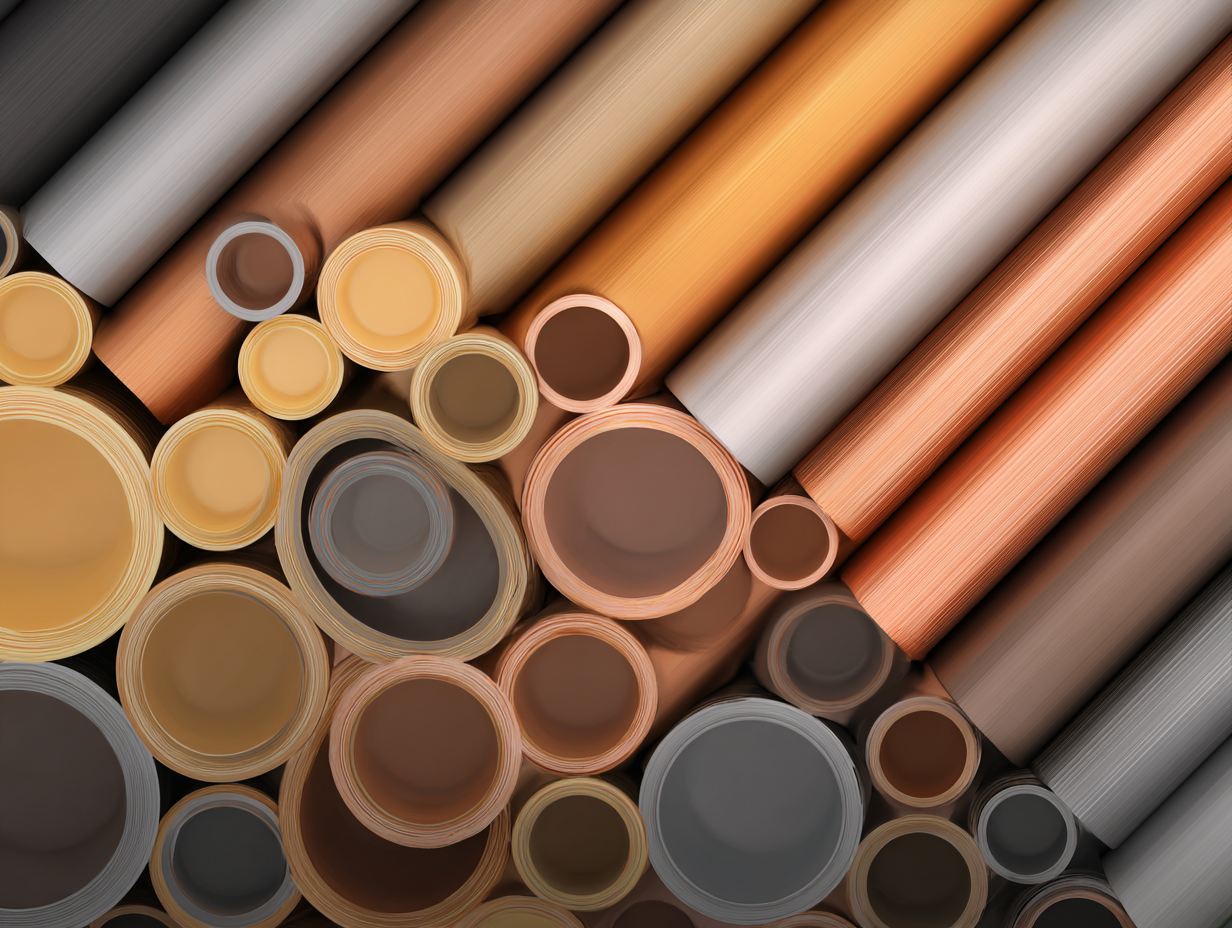

Types of Gas Piping Material

Selecting the right material is key to a safe and durable gas system. Each option offers unique benefits for specific applications.

Common Materials for Gas Systems

- Steel:

- Carbon Steel: Strong and ideal for high-pressure industrial systems, it dominates 40% of the global market, per Pipeline & Gas Journal.

- Stainless Steel: Corrosion-resistant, suited for outdoor or humid environments, used in 10% of transmission systems.

- Copper: Lightweight and corrosion-resistant, copper is popular for residential installations, making up 12% of home systems.

- Polyethylene (PE): Flexible and durable, PE excels in underground applications due to its resistance to moisture and chemicals, used in over 40% of new installations.

- Polyvinyl Chloride (PVC): Affordable for low-pressure uses, PVC holds a 5% market share but isn’t suited for high-volume systems.

Materials to Avoid

Avoid aluminum (prone to corrosion) and thin plastics (unable to handle high pressure) to ensure safety compliance.

Learn about PE piping benefits in our news article.

Gas Piping Sizing Guidelines

Proper sizing ensures efficient gas flow with minimal pressure loss. Key factors include:

- Gas Flow Rate: Measured in BTUs or MJ, homes need 150,000–250,000 BTUs per hour; industrial systems may require over 100 million.

- Pipe Length: Longer pipes increase pressure drop (1–3% per 100 feet), requiring larger diameters.

- Pressure Drop: Keep it below 5% for efficiency by adjusting pipe size.

Consult professionals or sizing charts to avoid issues. Explore more in our news section.

How Gas Pipes Work

Gas piping systems use pressure to deliver gas:

- Pressurization: Regulators control gas pressure for safe delivery.

- Flow Dynamics: Pressure drives gas through pipes of varying sizes.

- Valves and Meters: These regulate flow and monitor usage for accurate billing.

Understanding these mechanics aids in maintenance and troubleshooting.

Choosing the Best Gas Pipe for Your Needs

Compare gas piping options based on:

- Durability: Steel for high-pressure; PE for corrosion resistance.

- Cost: PE is cost-effective for underground systems; PVC is budget-friendly for low-pressure uses.

- Installation: PE is flexible for uneven terrain; copper is easy for residential setups.

Residential systems often use copper or PE, while industrial setups prefer steel. Explore piping solutions in our news updates.

Safety and Compliance in Gas Piping

Adhering to safety standards is critical. Regulations cover pressure ratings, materials, installation, and inspections. Avoid mistakes like incorrect material selection or poor sealing to prevent leaks.

For detailed safety guidelines, refer to the International Code Council.

Maintenance and Repairs of Gas Piping Systems

Regular maintenance ensures gas piping safety and efficiency:

- Check joints for leaks using detectors or soap solutions.

- Test system pressure regularly.

- Inspect pipes for corrosion, especially in harsh environments.

For repairs, experienced homeowners can handle minor fixes, but complex tasks require professionals. Find maintenance tips in our news section.

The Future of Gas Piping Technology

Innovations in gas piping include:

- Smart Pipes: Sensors detect leaks and pressure changes in real time.

- Eco-Friendly Materials: Biodegradable plastics reduce environmental impact.

With global gas infrastructure investments rising 4% annually, sustainable gas piping solutions are key.

Conclusion

Gas piping systems power homes, businesses, and industries. Selecting the right gas piping materials, ensuring proper gas piping sizing, and following gas safety standards guarantee reliability. With over 1,200 miles of pipelines added in North America in 2020, the industry is growing rapidly. Innovations like smart pipes promise a sustainable future.

For more insights on gas piping, visit our news page.