Gas Pipeline Systems

ENGINEERED FOR EXCELLENCE

Polyethylene gas pipes are made of PE 80 and PE 100 materials, and are intended for distribution of gas through a network, up to working pressure of 10 bar. The main performance characteristics of PE 80 and PE 100 gas pipes are determined by their material properties and applications.

PE 80 (Medium Density Polyethylene) are designed for medium-pressure applications and offer good flexibility and durability. PE 100 (High-Density Polyethylene) have higher density and strength compared to PE 80 and are designed for high-pressure systems.

GAS

Polyethylene gas pipes are made of PE 80 and PE 100, and are intended for distribution of gas through a network, up to working pressure of 10 bar.

Color: Black with longitudinal yellow lines, or yellow color for PE 80, and black with yellow lines or orange color for PE 100.

Standards: EN 1555-2 and ISO 4437.

PE 80 (Medium Density Polyethylene):

- Designed for medium-pressure applications.

- Offers good flexibility and durability.

- Suitable for smaller diameter and lower pressure systems.

PE 100 (High-Density Polyethylene):

- Higher density and strength compared to PE 80.

- Designed for high-pressure systems.

- Enables thinner wall thickness for the same pressure class, leading to reduced weight and cost savings.

- Longer service life due to improved resistance to stress cracking and environmental stress.

PE 80 is preferred for low to medium-pressure systems with smaller diameters, while PE 100 is ideal for high-pressure systems, larger diameters, and long-term, demanding applications.

Petroleum derivatives

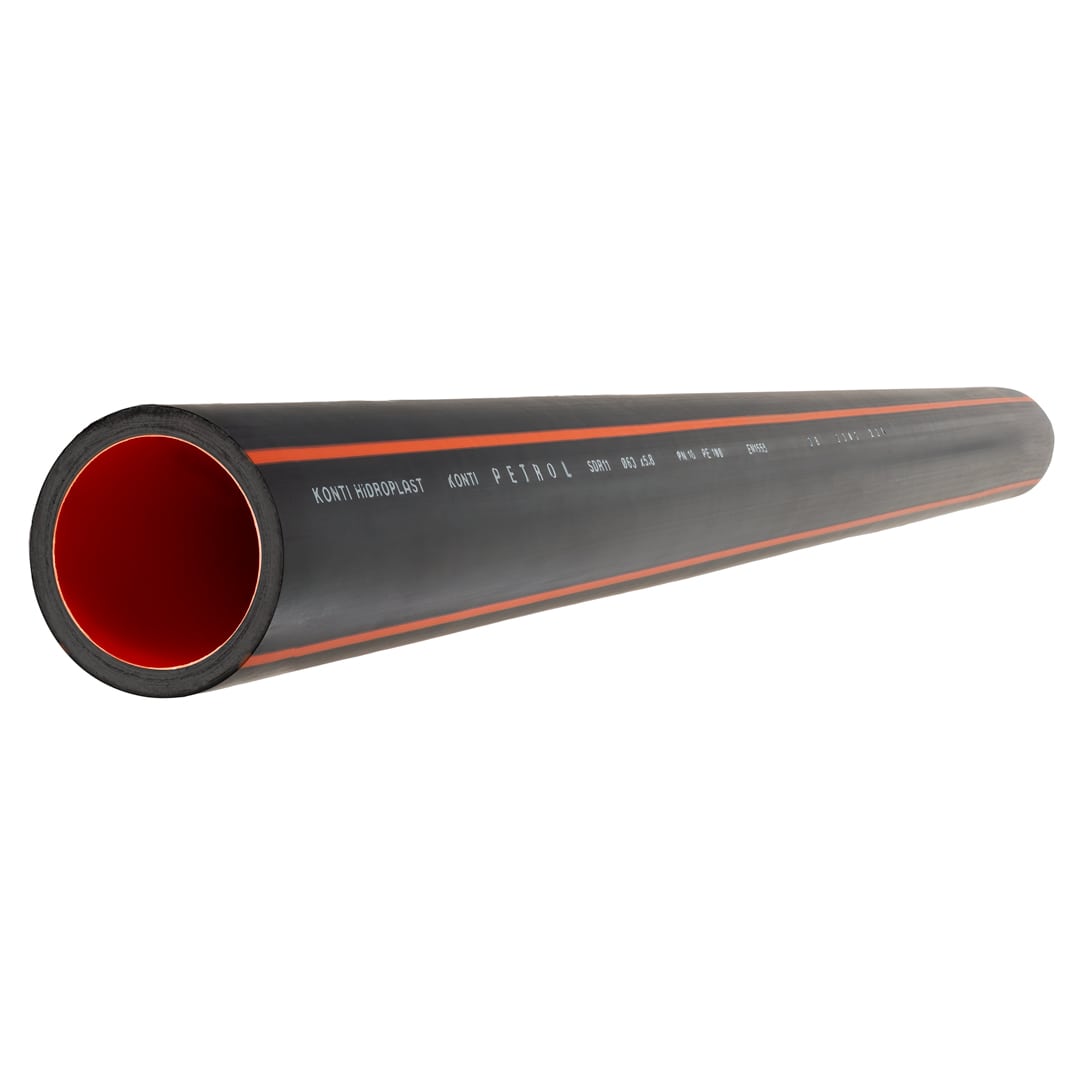

Konti Petrol gas pipe is a double-layered pipe with outer black surface made of PE100 standards, the same that apply for the classic PE i.e. EN 1555 or ISO 4437.

Color: Black with orange longitudinal lines on the outer layer, and orange inner layer.

Advantages of internal PE 100-X layer:

- Excellent resistance to volatile organic compounds from petroleum derivatives and prevents their crossing in the environment

- Protecting groundwater from impurities from the oil derivatives

- Resistance to extreme temperatures 35S to 85S

- Higher chemical resistance of the pipe

- Excellent resistance to abrasion

Application:

- Transport of petrol diesel and other fuels in stations and refinery

- Gas distribution

- Special industrial application

- Geothermal and city heating

Dimensions: PE100-PE100-X pipes are produced in dimensions from 20mm to 250mm

PE fittings

Fitting Stub Ends (Welding Collars)

Fitting Stub Ends (Welding Collars)

Fitting – Concentric Reducer

Fitting – Concentric Reducer

Fitting – End Cup

Fitting – End Cup

Fitting – Tee Outlet Without Reinforcement

Fitting – Tee Outlet Without Reinforcement

Fitting – Tee Outlet Reducer

Fitting – Tee Outlet Reducer

Fitting – Tee Outlet

Fitting – Tee Outlet

Electrofusion Adapter Socket Integrated Welding Module Male Thread Out Of Brass

Electrofusion Adapter Socket Integrated Welding Module Male Thread Out Of Brass

Electrofusion Adapter Elbow 45° Integrated Welding Module Male Thread Out Of Brass

Electrofusion Adapter Elbow 45° Integrated Welding Module Male Thread Out Of Brass

Electrofusion Adapter Elbow 90° Integrated Welding Module Male Thread Out Of Brass

Electrofusion Adapter Elbow 90° Integrated Welding Module Male Thread Out Of Brass

Tapping Saddle With Electrofusion Sealing Cap Integrated Welding Module

Tapping Saddle With Electrofusion Sealing Cap Integrated Welding Module

Universal Tapping Valve With Thread Insert Out Of Brass Integrated Welding Module

Universal Tapping Valve With Thread Insert Out Of Brass Integrated Welding Module

Plastic Tapping Valve With Integrated Cutter Integrated Welding Module

Plastic Tapping Valve With Integrated Cutter Integrated Welding Module