PP ML COMPACT PIPE

ENGINEERED FOR EXCELLENCE

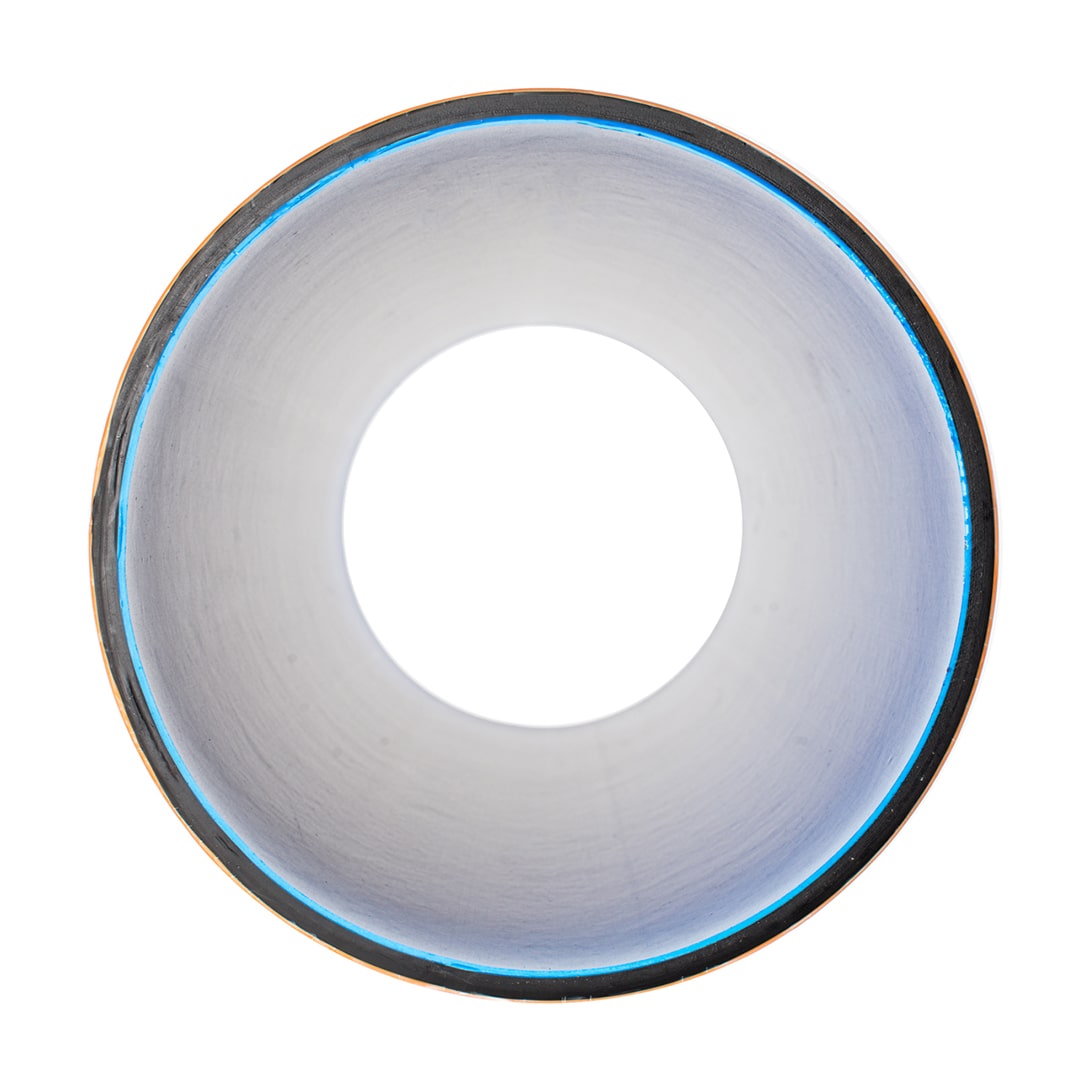

PP ML (Polypropylene Multi-Layer) solid pipes are designed specifically for sewage and drainage systems, offering a combination of durability, efficiency, and environmental sustainability. PP ML compact pipe is made of high module polypropylene (PP-HM) as its basic material, with three layers. Each of the three layers has a different modified formula of the basic material, which gives specific performances in the entire quality of the pipe.

Production standard:

- EN 13476-2 :2007 (Type А1)

- ONR 201513:2011

TRIPLE-LAYERED PIPE

PP ML (Three-Layer) solid pipes provide a robust, efficient, and eco-friendly solution for modern sewage systems. Their combination of structural strength, hydraulic performance, and chemical resistance makes them ideal for both municipal and industrial wastewater applications.

- INNER LAYER: Made of modified PP with guaranteed high chemical and abrasive resistance. The smooth surface ensures good flow and prevents deposits.

- MIDDLE LAYER: Impact resistant layer, even at low temperatures.

- OUTER LAYER: Made of high quality PP, filled with mineral modifier; highly resistant to atmospheric agents and surface damaging. The modified PP formula ensures high UV protection, allowing external storage.

Application:

- Residential, municipal, and industrial wastewater systems.

- Stormwater management and subsoil drainage.

- Transport of chemical effluents and process water.

- High-load applications like culverts under roads and railways.

Characteristics:

- Color: Outer orange-brown/middle black and inner light color or different according customer request.

- Dimensions: from DN / OD 160 to 500 mm with a complete range of fittings.

- Available in different classes of incompressibility: ЅN 8 КN\m2; ЅN 10 КN/m2; ЅN 12 КN/m2 and ЅN 16 KN/m2

- Manning’s coefficient typically around 0.009, reducing clogging and ensuring a self-cleaning effect.

- Expected service life exceeds 50 years under normal conditions.

- Suitable for above-ground and exposed installations with UV-stabilized outer layers.

- Can operate between -20°C and +90°C, with short-term resistance to higher temperatures.

- Fully recyclable material and energy-efficient production.